Products

Showing 1–12 of 117 results

-

ASME Orifice Plate

Read more ASMEASME Orifice plates are designed with tappings for pressure measurement devices, making them essential for flow rate measurement in pipelines.

- Standard Size: 1/2” To: 60”

- Face: RF – FF – RTJ

- Class: 150 To: 2500

- Material: ASTM A105 – ASTM A350 – ASTM A694 – ASTM 266 – ASTM A182 F316 – ASTMA 182 F304.

-

Nipple Fitting

Read more Low PressureNipple fittings are pipe fittings produced by heating and bending the pipe to achieve a specific radius and change the direction of flow, often used for large diameter pipes or when specific bend radii are required, typically in lower pressure applications

Range:

¼’-24 (SMLS)

26’ – 48’ WELDED.

Material:

SS/C.S-FORGED/REINFORCED.

SS/C.S-WROUGHT.

SS-WROUGHT.

C.S.

ALLYOYS/C.S/SS/DSS/SDSS-HIGH TEMP/ LOW TEMP ALLOYS.

Grade:

ASTM A234WPB,A420 WPL6 A860-GR WPHY 42,52,60,65 F9,F11,F22,F52.

ASTM A234WPB,A420 WPL6 A860-GR WPHY 42,52,60,65.

ASTM A403 GR-304/304L,321/H,904/L&316/316L.

ASTM A234 WP1,WP5,WP9,WP11,WP22,WP91.

ASTM A815 UNS 31803, UNS 32750/32760.

-

Single Nipple Fitting

Read more High PressureSingle Nipples are short pipe fittings with male threads on both ends of different sizes, designed to connect two female threaded fittings of dissimilar diameters within a piping system, particularly in high-pressure applications.

Material:

SS/C.S-FORGED/REINFORCED,

SS/C.S-WROUGHT,

SS-FORGED

Range:

Up To – 4″ (Forged)

Grade:

ASTM A 105/A182 F9,F11,F22,F52.

ASTM A182 F304/304L F316/316L.

-

Hose Nipple Fitting

Read more High PressureHose Nipple are short pipe fittings with male threads on both ends and a hexagonal section in the middle, designed for connecting two female threaded fittings, particularly in high-pressure systems, allowing for wrench tightening.

Material:

SS/C.S-FORGED/REINFORCED,

SS/C.S-WROUGHT,

SS-FORGED

Range:

Up To – 4″ (Forged)

Grade:

ASTM A 105/A182 F9,F11,F22,F52.

ASTM A182 F304/304L F316/316L.

-

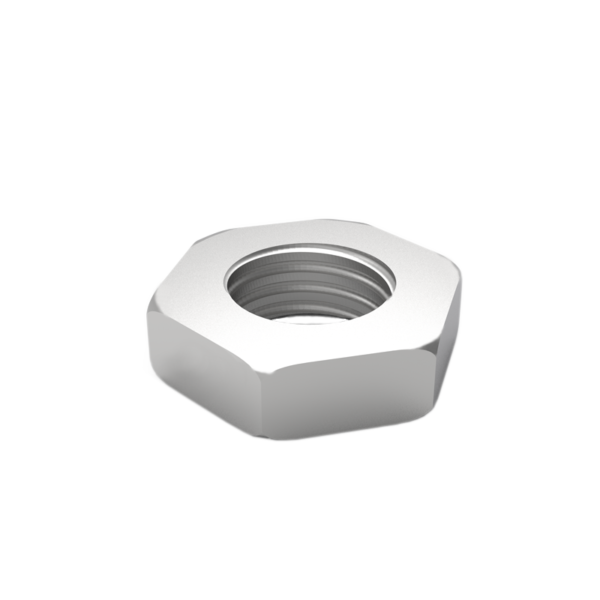

Lock Nut Fitting

Read more High PressureLock Nut are pipe fittings designed to join two pipes of the same diameter together in a straight line using a socket welding method, particularly in high-pressure systems, providing a strong and leak-tight connection.

Material:

SS/C.S-FORGED/REINFORCED,

SS/C.S-WROUGHT,

SS-FORGED

Range:

Up To – 4″ (Forged)

Grade:

ASTM A 105/A182 F9,F11,F22,F52.

ASTM A182 F304/304L F316/316L.

-

Metal Double Jacketed Gaskets

Read more Semi-MetallicMetal Double Jacketed Gaskets are durable seals consisting of a metallic outer jacket enclosing a soft filler material, providing a reliable seal for various industrial applications.

- Range: ½” to: 48”

- Material: Jacket: SS, Soft Filler: Graphite/PTFE

- Class: up to 1440 PSI

- Standards: ASME B16.20

-

Ring-Joint Type (BX) Gasket

Read more MetallicRing-Joint Type (BX) Gasket are high-integrity metallic seals designed for high-pressure and high-temperature applications in flanged connections, providing a reliable and robust sealing solution.

- Range: BX-150 To BX-303

- Material: Carbon Steel, SS304/316, Inconel, Monel

- Standards: API 6A, ASME B16.20

-

Flange Nut Fastener

Read more Fasteners-subFlange Nuts are durable fastening components designed to distribute load evenly and enhance joint stability without the need for additional washers. Commonly used in structural, industrial, and heavy-duty applications, flange nuts provide strong resistance to loosening under vibration and are manufactured to meet international quality and performance standards.

- DIN Standard: 934 ASTM A194 (2H)

- Diameter Range: M6 – M24

- Grade: 5, 8, 10

- Surface Treatment: Plain – Black, Z.P, H.D.G

-

Flange Bolt Fastener

Read more Fasteners-subFlange Bolts are high-strength fasteners designed to provide secure and even load distribution through an integrated flange, reducing the need for separate washers. They are widely used in structural, automotive, and industrial applications where reliable fastening and vibration resistance are required. These bolts are manufactured in accordance with international fastening standards to ensure durability and performance.

- DIN Standard: 933

- Diameter Range: M6 – M24

- Length Range: 16mm – 250mm

- Grade: 4.8, 8.8, 10.9

- Surface Treatment: Plank– Black, Z.P, H.D.G

-

Hot Bend Fitting

Read more Low PressureHot Bends are pipe fittings produced by heating and bending the pipe to achieve a specific radius and change the direction of flow, often used for large diameter pipes or when specific bend radii are required, typically in lower pressure applications

Range:

¼’-24 (SMLS).

26’ – 48’ WELDED.Material:

SS/C.S-FORGED/REINFORCED.

SS/C.S-WROUGHT.

SS-WROUGHT.

C.S.

ALLYOYS/C.S/SS/DSS/SDSS-HIGH TEMP/ LOW TEMP ALLOYS.Standards:

ASTM A234WPB,A420 WPL6 A860-GR WPHY 42,52,60,65 F9,F11,F22,F52.

ASTM A234WPB,A420 WPL6 A860-GR WPHY 42,52,60,65.

ASTM A403 GR-304/304L,321/H,904/L&316/316L.

ASTM A234 WP1,WP5,WP9,WP11,WP22,WP91.

ASTM A815 UNS 31803, UNS 32750/32760. -

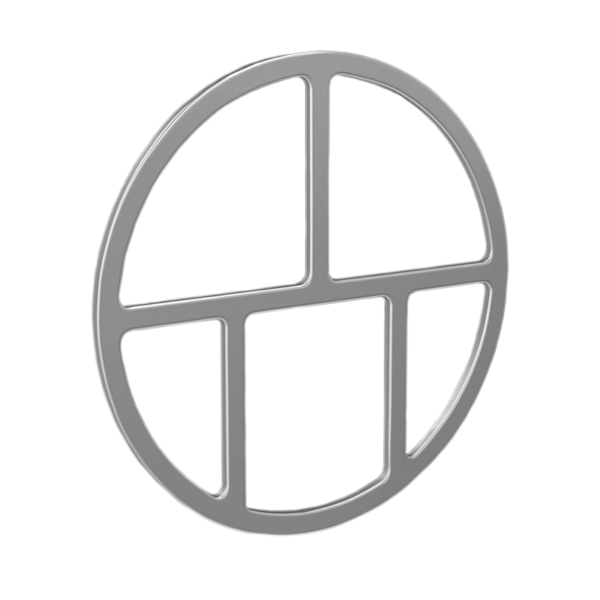

Equal Cross Tee Fitting

Read more Low PressureEqual Cross Tees are pipe fittings with one inlet and three outlets of the same diameter, used to create two branch connections at 90-degree angles in a piping system, typically in lower pressure applications.

Range:

¼’-24 (SMLS).

26’ – 48’ WELDED.Material:

SS/C.S-FORGED/REINFORCED.

SS/C.S-WROUGHT.

SS-WROUGHT.

C.S.

ALLYOYS/C.S/SS/DSS/SDSS-HIGH TEMP/ LOW TEMP ALLOYS.Standards:

ASTM A234WPB,A420 WPL6 A860-GR WPHY 42,52,60,65 F9,F11,F22,F52.

ASTM A234WPB,A420 WPL6 A860-GR WPHY 42,52,60,65.

ASTM A403 GR-304/304L,321/H,904/L&316/316L.

ASTM A234 WP1,WP5,WP9,WP11,WP22,WP91.

ASTM A815 UNS 31803, UNS 32750/32760. -

U Bends Fitting

Read more Low PressureU Bends are pipe fittings with a U-shape used to change the direction of flow by 180 degrees with a specific center-to-center distance between the legs, typically in lower pressure applications

Range:

¼’-24 (SMLS).

26’ – 48’ WELDED.Material:

SS/C.S-FORGED/REINFORCED.

SS/C.S-WROUGHT.

SS-WROUGHT.

C.S.

ALLYOYS/C.S/SS/DSS/SDSS-HIGH TEMP/ LOW TEMP ALLOYS.Standards:

ASTM A234WPB,A420 WPL6 A860-GR WPHY 42,52,60,65 F9,F11,F22,F52.

ASTM A234WPB,A420 WPL6 A860-GR WPHY 42,52,60,65.

ASTM A403 GR-304/304L,321/H,904/L&316/316L.

ASTM A234 WP1,WP5,WP9,WP11,WP22,WP91.

ASTM A815 UNS 31803, UNS 32750/32760.